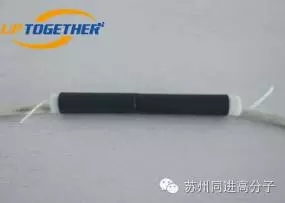

Operation description of double head EPDM cold shrink tube s

Case name: two insulated connections for low voltage cables

Applicable engineering: two connections of low voltage two cables.

Application location: cable connection

Classic users: foreign customers

Application: The EPDM cold-shrinkable pipe with double-pull head is made of cold-shrinkable silicone rubber pipe. The finished silicone rubber pipe is expanded to two well-welded support bars. When used, the position is fixed and the support is pulled out. The scheme has the following advantages:

1. the double head EPDM cold shrink tube has a unique double drawing structure, and the positioning is very accurate.

2. The strong, tough and elastic rubber of the cold-shrinkable pipe keeps its sealing pressure and permanent radial pressure even when exposed to the outside, so that the joint can still keep the suit when swinging in the wind.

3. The cold-shrinkable pipe does not need heat source and other special tools. It can be used to extract the support bar, which greatly reduces the installation workload and working time, and is easy to remove when it needs to be detected or disconnected. In short, the installation is very convenient, easy to understand, do not need special training, new people can quickly learn to install, and can ensure the installation of high quality.

4. Excellent cold shrinkage management performance, antibacterial, ozone and acid and alkali resistance, good thermal stability, excellent weather resistance, excellent wear resistance.

5. Because of the large shrinkage range, the cold shrinkage pipe is usually between 3 and 5 times. The large application range can be applied to a variety of cable sizes, reduce the type of corresponding, reduce the purchase inventory cost.

Products directly through: EPDM cold shrink tube silicone rubber shrink tube (click the link can be checked)

Description of operation and installation of double head EPDM cold shrink tube:

1. Cool the shrink tube on the cable.

2. Install the connection connector and clean the insulation skin on both sides of the cable joint.

3, mobile cold shrink tube, set at the cable junction.

4. In the desired initial contraction position, hold the cold pipe and cable in one hand, and pull the other hand to support the welded pipe.

5, continue the installation at the other end.

6, complete the installation.

Copy the following links to scan the following two-dimensional code into the store consultation.

Uptogether.taobao.com

Cold shrink sales Xiao Yang, telephone (WeChat): 18962507872, QQ:2410325846

The copyright of this article belongs to Suzhou Tongjin Polymer Material Co., Ltd. The reprint must indicate the origin, please respect the author's hard work. (www.uptogether.com.cn)

English

English  简体中文

简体中文